Vector Engraving

With vector engraving we can mark or score a material’s surface. A similar process with laser cutting is following to configure the laser beam to track the path of vector lines, just stopping short from cutting all the way through the material. The thickness of the line that can be engraved is around 0.2mm. To engrave thicker lines the raster engraving method is used.

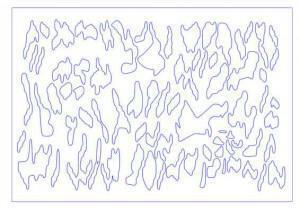

1. Prepare your pattern

You send us your pattern or drawing in order to check it and see if it’s appropriate according to our laser cutter and the material you intend to use. The laser cutter reads vector lines that need to be set on ‘hairline thickness’ or 0.01mm and in blue color to denote ‘engrave’ and not ‘cut’.

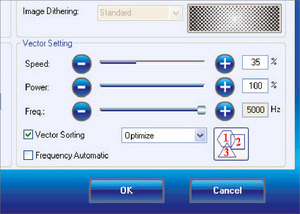

2. We configure the laser settings

According to the material of your choice we configure the laser to the appropriate engraving power, speed and frequency settings. The debth of engraving can vary, depending on the material, and you can tell us if you want to barely mark the surface or engrave almost entirely through.

Vector engraving can be processed simultanuesly with a cutting job, provided you denote via red and blue colors the difference in your pattern.

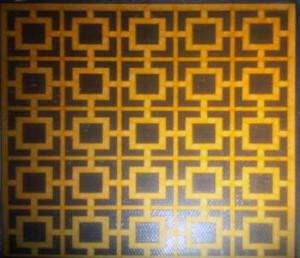

3. We process your job

The machine then traces the blue paths of your drawing lines to cut out the patterns you have drawn. If any cuts are also included in the job they are processed afterwards.

Depending on the material, we might need to use a protective membrane that can be removed once the cutting is over, in order to protect the material surface from any burn marks.

4. Collect your design

You collect your design laser-cut on your material of choice, or we deliver it to your location of choice.